1. Why Choose Induction Lights?

1. Maintenance

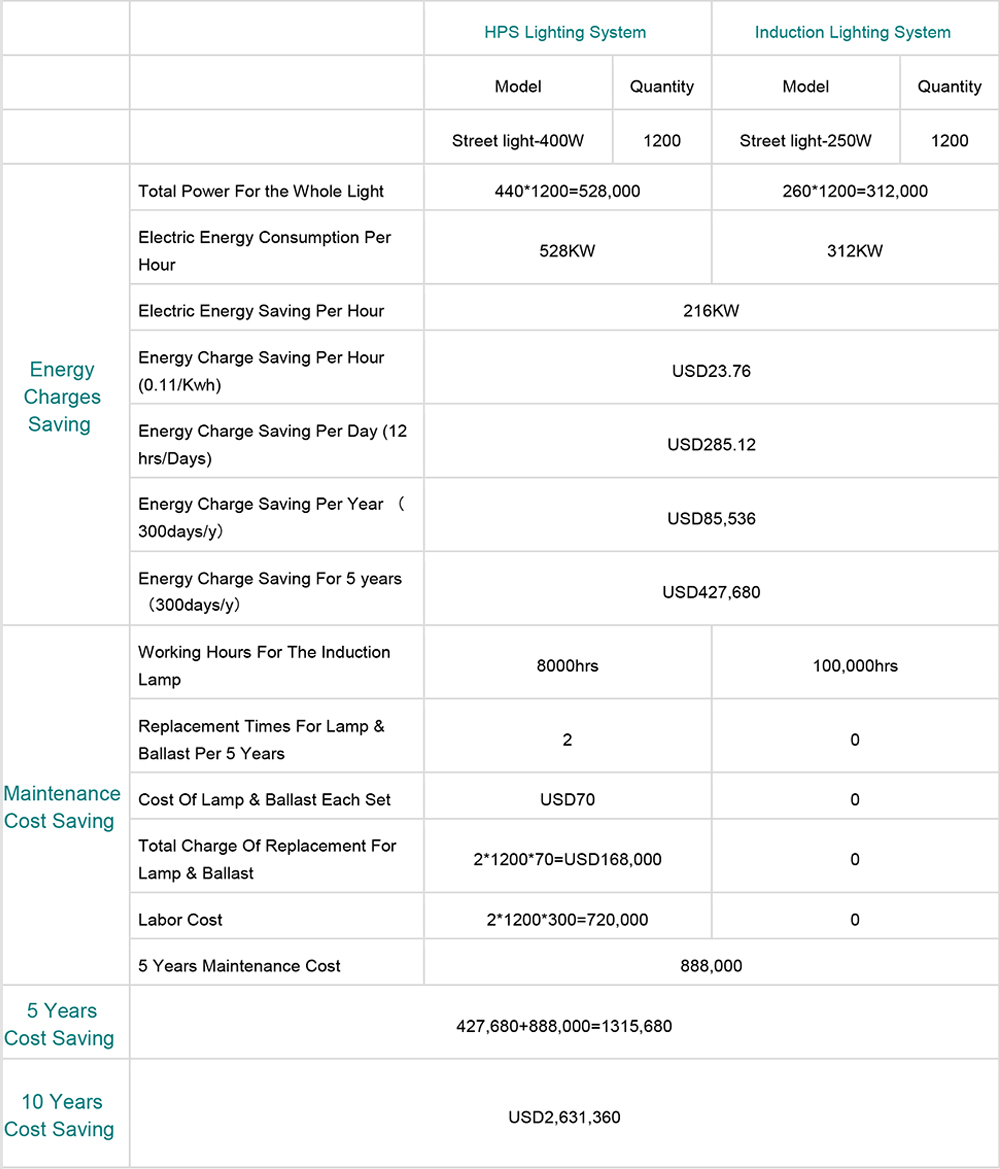

With over 100,000 hours of life, induction lamps are highly reliable and practically maintenance free. In most cases, this saving alone will more than offset the initial cost of the induction system.

2. Efficiency Producing 150 pupil lumens of light for each watt of energy, induction lamps offer energy savings of 50%, compared to conventional sodium/metal halide.

3. Brightness Offering crisp white light with a CRI index of 80+ and a choice of 2700K, 3500K, 5000K and 6500K colour temperatures, this makes colours appear brighter and more vibrant.

4. Instant Induction lamps respond instantly to being switched on or off, with no lengthy waiting times.

2. What is the induction light system and how does induction lighting work?

The induction lamp uses revolutionary light technology that combines the basic principles of induction and gas discharge. Induction technology avoids the use of electrodes, which allows for an unprecedented 100,000 hours of high quality white light.

3. Do induction lights need a dedicated fixture?

Induction lights and ballasts can be fitted into existing fixtures and housings. Please ensure that the existing reflectors are in good order otherwise we cannot guarantee lumen output.

4. What are the components of the system?

The system comprises of three components: the ballast, the magnetic rings and the lamp tube.

The magnetic rings transfer energy from the high frequency ballast to the discharge gas inside the glass tube, using an antenna that contains the primary induction coil and its ferrite core.

The rings also have a heat–conducting rod with a mounting flange which allows the induction lamp system to be mechanically attached to the luminaries.

5. Can induction interfere with computers, telecommunications or other electronic Device?

No. Induction systems run at 250 kHz which complies with FCC and CE (EMC) Regulations with non–interference under normal circumstances.

6. Is the light output of an induction lamp affected by temperature?

The lamp amalgam fill technology and the heat–conduction rod in the centre creates a stable light output over a wide temperature range maintaining at least 85% of normal lumen output from -40°C and +40°C.

7. How long will the Induction lamp last?

Induction lighting systems are designed to have an average rated life of 100,000 hours at a maximum ballast case temperature of 65°C.

Typically:

-external systems (Separate ballast) – 100,000 hours

-internal systems – (Separate ballast) – 80,000 hours

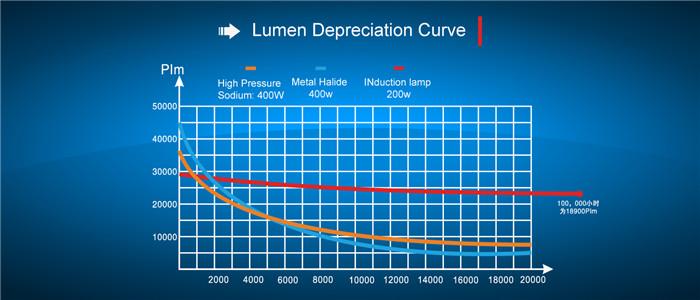

8. What is the typical Lumen maintenance?

The lumen output of the induction lamp is expected to depreciate after 80,000 hours to 80% of the initial rated lumens (or 20% lumen depreciation).

When a fluorescent lamp is new its light output is at its maximum, as the lamp operates, various processes (plasma, chemical and thermal) within the lamp cause a gradual reduction of lumen output. The degree to which the actual light decreases with operating time is referred to as the lumen maintenance.

9. What type of gas is used inside the lamp?

A mixture of inert gases such as Argon.

10. Does the operating position affect the Lumen output?

No. The universal operating position does not affect the performance of the induction lamp system. The reflector of the fixture is used to direct the light to a designated area.

11. Is the induction light dimmable?

Yes. In theory the induction lamp system is able to dim to 30% of the normal lumen output.

However, we would not recommend dimming as this would severely reduce the life of the ballast.

12. Is the induction lamp vibration resistant?

Yes. As induction lamps do not have electrodes, they are more reliable in high vibration applications. The induction lamp has proven durability in all external applications.

13. Do voltage supply fluctuations effect the performance of the Induction system?

The IC (Integrated Circuit Board) in the ballast guarantees stable current under voltage fluctuations from 170V – 250V. There is no noticeable affect in the light performance (Colour Temperature CRI) as a result of voltage fluctuations.

14. How can induction lights be disposed of at the end of their life span?

Light: Although a very small amount of Mercury is used, it is recommended to treat the lamp as small chemical waste. The lamp can be recycled together with other low-pressure discharge lamps. Follow local authority regulations for disposal of this type of light source.

Ballast: This component is a RoHS compliant device, which can be disposed of with normal care. It is recommended to dispose of the ballast as normal electronic waste according to local authority regulations.

15. At the end of life must all of the components be replaced?

Although all components are separately replaceable, induction lamps are almost always supplied as a system, even for re- lamping. End of life usually means the ballast must be replaced, and at that time it is usually recommended to replace the lamp as phosphor degeneration at 100,000 hours lowers lumen output to 35% - 40%.

16. Why is induction technology worth more?

Induction lighting systems offer five to ten times the life of HID systems for only two to three times the cost of the HID lamp and ballast.

For More Information

Contact us for more information or to arrange an on-site demonstration on power saving.